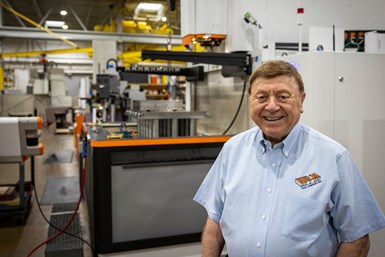

Innovation, leading technology, craftmanship and expert employees are key to Helm Tool’s 45-plus year history. Photo Credit, all images: Creative Technology Corp.

Who is Helm Tool?

Helmut Mueller, president, Helm Tool Company: Since 1977, Helm Tool has worked hard to take mold manufacturing to a higher standard. We are widely known for building cutlery molds of any size and combination, but we also build tooling for the automotive, electrical, electronics, medical, optical, consumer goods and recreational markets.

Helm Tool continuously invests in machine technology including large five-axis milling and ultra-precision, high-speed machining centers from DMG MORI, Hermle, Roeders, Makino and Hamai.

Mold types include injection molds with direct gating hot to cold or cold runner systems, stack, unscrewing, shuttle, transfer, rotating two-color and compression, molds with side cores and lifters and die-cast dies for aluminum, magnesium and zinc.

We use all of the latest technology and concepts for greater accuracy and higher productivity, including high-performance machining for fast material removal, five-axis milling for efficient roughing and finishing, high-speed milling for machined to finished surfaces, sinker and wire EDMs, large-capacity surface grinding, one-and-done mill-turn machines for faster, more accurate round cores and inserts and even waterjet cutting for fast and accurate plate work.

Intermolding Technology's knowledgable staff, and low-cost, fast-delivery and 5S production efficiency are key to its plastic injection molding services.

Helm Tool’s 94,000-square-foot climate-controlled facility in Schaumburg, Illinois, also houses Intermolding Technology. This division provides in-house mold tryouts, prototypes, early sampling and production and high-volume production.

Helm Tool employs about 30 people, with additional employees in the Intermolding division.

Share some of your background.

Mueller: I have 50 years of experience in plastic injection molds, die-casting and process development rooted in German work ethic, quality and craftsmanship, which taught me that to be successful, you must make enough money so you can train your people and replace old equipment with cutting-edge technology.

Helmut Mueller learned quickly that he wanted to own his own shop, so he started Helm Tool Company and still serves as president.

While working at a machine building and die shop, doing research and development during the day and studying engineering at night in 1960s Berlin, I got my first glimpse of the American dream from an unlikely source — a Sears catalog. I looked at the catalog and saw how much money you can earn and what you can buy. The products the catalog promoted offered me the promise of a high standard of living, which brought me to the United States in 1965, where a sponsor landed me work in a body shop. Eventually, I found work in a tool shop building molds and dies in the Greater Chicago area and strived to learn as much as possible about each process and how to best leverage every piece of equipment.

50 years of experience in plastic injection molds, die-casting and process development rooted in German work ethic, quality and craftsmanship.

It didn’t take me long to realize that I didn't want to be an employee; instead, I wanted to have my own company. So in 1977, I started Helm Tool Company and still serve as president. The company’s approach from the beginning was high-quality and innovative engineering in mold design to offer customers the best and most economical solution. We continuously reinvest in new technology and equipment to maintain our leadership role, including high-speed milling, EDM, and five-axis machines and automation. In addition, our people are a crucial part of our continuous improvement, routinely participating in seminars and training to learn the latest processes and techniques.

What do you view as Helm Tool's chief competitive advantage?

Mueller: Our core competitive advantage is the team’s extensive knowledge of moldmaking and ways to maximize materials, equipment and talent that leads to collaborative, innovative mold designs. By knowing to better design a part, machine that part and maintain the part, we can operate the most efficient process.

It isn’t unusual for us to leverage multiple departments to ensure everything will operate smoothly instead of bringing problems from department to department. For example, the EDM department works closely with the part designer to ensure that best steps are taken to prevent errors or long-running processes. We also develop ways to use our machines to work multiple parts in one setup.

Intermolding Technology, now housed with Helm Tool, offers full molding capabilities for custom molding and mold sampling with a fully equipped tool room for mold repair and plastic part machining.

Explain the reason(s) for your recent expansion and bringing both companies under one roof.

Mueller: I knew it was time to expand when Helm Tool’s building became too cumbersome for people to move around in, and when the constant back-and-forth of molds from Intermolding Technology in a building three miles away impacted productivity.

What recent changes have you made in your approach to the business?

Mueller: (1) More in-house capabilities. We invested in technology to bring more capabilities in-house, improving our productivity. For example, purchasing our five-axis machine eliminated the bottlenecks we had from outsourcing our mold base work. Purchasing a large surface grinder solved another bottleneck area, as it allowed us to do grinding ourselves and shortened lead times.

Helm Tool offers in-house mold maintenance and surface treatment, including polishing.

(2) Custom molding. With the launch of Intermolding Technology, we are now a multidisciplinary manufacturer. We can do custom molding and sampling from 35 to 600 tons in-house. The presses we own enable us to test, sample and prototype any mold we need to without having to find machine availability on the outside.

Our services include production injection molding (hot runner or conventional runner tools), custom short molding runs, prototype samples, assembly and labeling with 24/7 capabilities. In addition, parts can be stored until production is needed at our large Schaumburg warehouse.

Our plastic engineering capabilities include product design, development, tooling and prototyping. We also offer material selection assistance and are equipped to handle small and large orders, including secondary operations (e.g., ultrasonic welding, assembly, product packaging and fulfillment) and our quality management system ensures that parts meet or exceed customer specifications.

Our primary markets include consumer products (disposable and durable), industrial, commercial and defense for significant companies like AM General, ITT, ITW and Kimberly Clark.

The team strives to help each other grow to become well-rounded machinists, toolmakers or engineers through continuous training, job shadowing and ongoing education.

We are in the process of building an inspection lab and adding a CMM to monitor the production quality within the required specifications.

(3) Cross-training. Because labor is hard to find, we focus on cross-training. Our seasoned moldmakers train new employees across all departments. This approach enables us to maximize the skills of each team member and prevent downtime if someone takes a vacation or is sick.

Helm Tool is widely known for building cutlery molds of any size and combination, but they also build tooling for the automotive, electrical, electronics, medical, optical, consumer goods and recreational markets.

Why is mold maintenance important for Helm Tool and how do you manage preventative maintenance (PMs)?

Mueller: As I said, we are known for our cutlery molds — high-speed molds that run 24/7. Currently, we have five customers for which we build 100% of their molds. Some of these molds last two to three years, while others last 15 years, depending on the customer’s maintenance plan. Some customers send their molds to us for proper maintenance. Depending on the wear or damage, we use our in-house grinders, high-speed mills and laser welder to resurface. We outsource hot runners for repair.

What are some career opportunities at Helm Tool?

Mueller: We are looking for passionate people who want to continuously build into their careers, drive innovation and further support our customers and the industry. The team strives to help each other grow to become well-rounded machinists, toolmakers or engineers through continuous training, job shadowing and ongoing education. We are looking for first-shift, experienced and apprentice moldmakers and machinists (CNC mill, high speed, five-axis, sinker and wire EDM, CNC lathe, and surface and cylindrical grinding).

Related Content

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MorePrecision Welding Services Offer Rapid Turnaround Mold Repair and Reduced Molder Downtime

X-Cell Tool & Mold relies on outsourced, high-quality welding repairs from Lewis-Bawol Welding to ensure its customers' molds are back in production quickly and affordably.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreRead Next

Thermoset Mold Builder Takes on EV Market

New Dynamics and NDC International provide complete tooling and molding solutions for the electric vehicle market and electronic encapsulation technology.

Read MoreIndiana Mold Builder Decatur Mold Offers a History of Grit and a Future of Innovation

Decatur Mold Tool and Engineering Inc. serves as a tooling tour guide, helping busy tooling managers reduce uncertainty, lighten workload.

Read MoreA Conversation with Big 3 Precision Products Inc.

MMT interviews Big 3 Precision Products Inc., a group that builds injection blow molds, one- and two-step injection stretch blow molds and extrusion blow molds.

Read More

.jpg;maxWidth=300;quality=90)